S.E.A. Co., Ltd.

Industrialization, globalization, digitalization, these are keywords for the last big tranformations in human life. Ecologization might be a next one. Fighting the climate change still requires much more transition from fossile and nuclear energy ressources to renewable ones such as solar power. But also continuous development of semiconductor technolgies remains a key to make technical systems smarter, more powerful, and less energy consuming.

As a company of experts for wetchemical surface treatment SEA is engaged in photovoltaic, semiconductor, PCB, and glass industries. SEA builds high-end production machines that can treat various substrates – as they are used in the mass production of solar cells, glass panels, and semiconductor devices – with chemistries for cleaning, etching or electrochemical deposition.

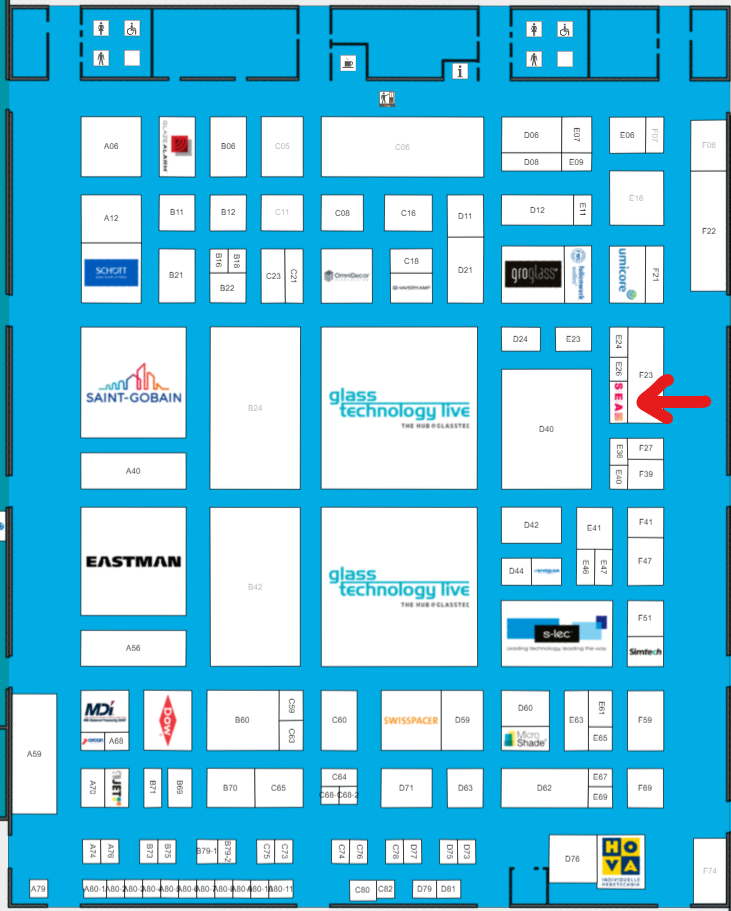

Were are we?

Hall 11 with booth no. E28

Read more about our products…

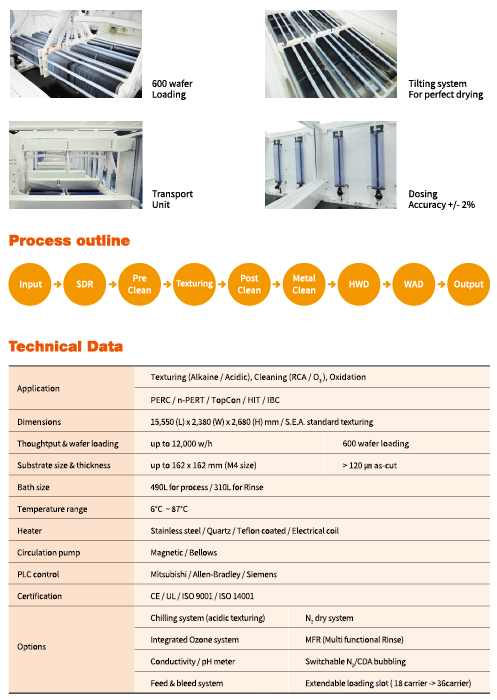

PHOTOVOLTAIK TEXTURING CLEANING. Our SEAline Glass Cleaner platform is designed for particle free inline transportation of big glass panels up to Generation 7, as they are used in Thin Film In the PV industry S.E.A. offers two machine platforms for the manufacturing of solar cells. The Batch XL platform is an ultra capacity batch equipment for highest cost performance and optimized for high efficiency (n-type) solar cells. The Inline XL platform is an optimized system for n-type inline applications. Both machine platforms are available for Si wafer sizes up to M12 (210x210mm) and offer various texturing and cleaning processes.

SEMICONDUCTOR MANUFACTURING. The SEAbatch SEMI platform is an ultra capacity batch equipment for highest cost performance. The proven machine platform is available for Si wafers up to 300mm as well as glass and ceramics supstrates up to 500x500mm. It offers process solutions for cleaning, developing, etching, stripping, oxidation, and special drying.

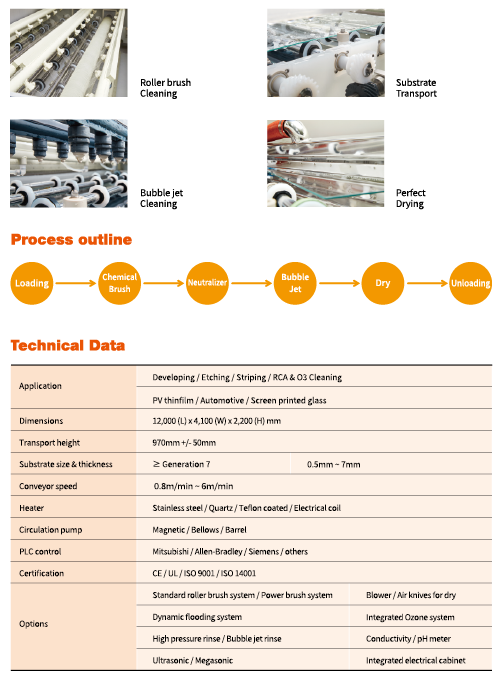

THIN FILM PV MANUFACTURING. Our SEAline Glass Cleaner platform is designed for particle free inline transportation of big glass panels up to Generation 7, as they are used in Thin Film PV and Flat Panel Display manufacturing. The platform offers various process solutions for cleaning, etching, developing, and stripping applications. With its SEAline Glass Cleaner S.E.A. is the key supplier of one of the world’s biggest manufacturers of thin film PV panels.

Contact us

If you have any questions about our products, applications, or S.E.A. Group itself, please feel free to contact us.

We are looking forward to hearing from you.

Website: www.sea-group-europe.com

Email: info@sea-group-europe.com

+49 (0) 160 6367673